Construction gypsum is the main raw material of gypsum board. After processing into a board, an appropriate amount of additives and fibers made from the board core are added to the special board paper for protection. Gypsum board has the characteristics of light weight, sound insulation, heat insulation, strong processing performance and simple construction method.

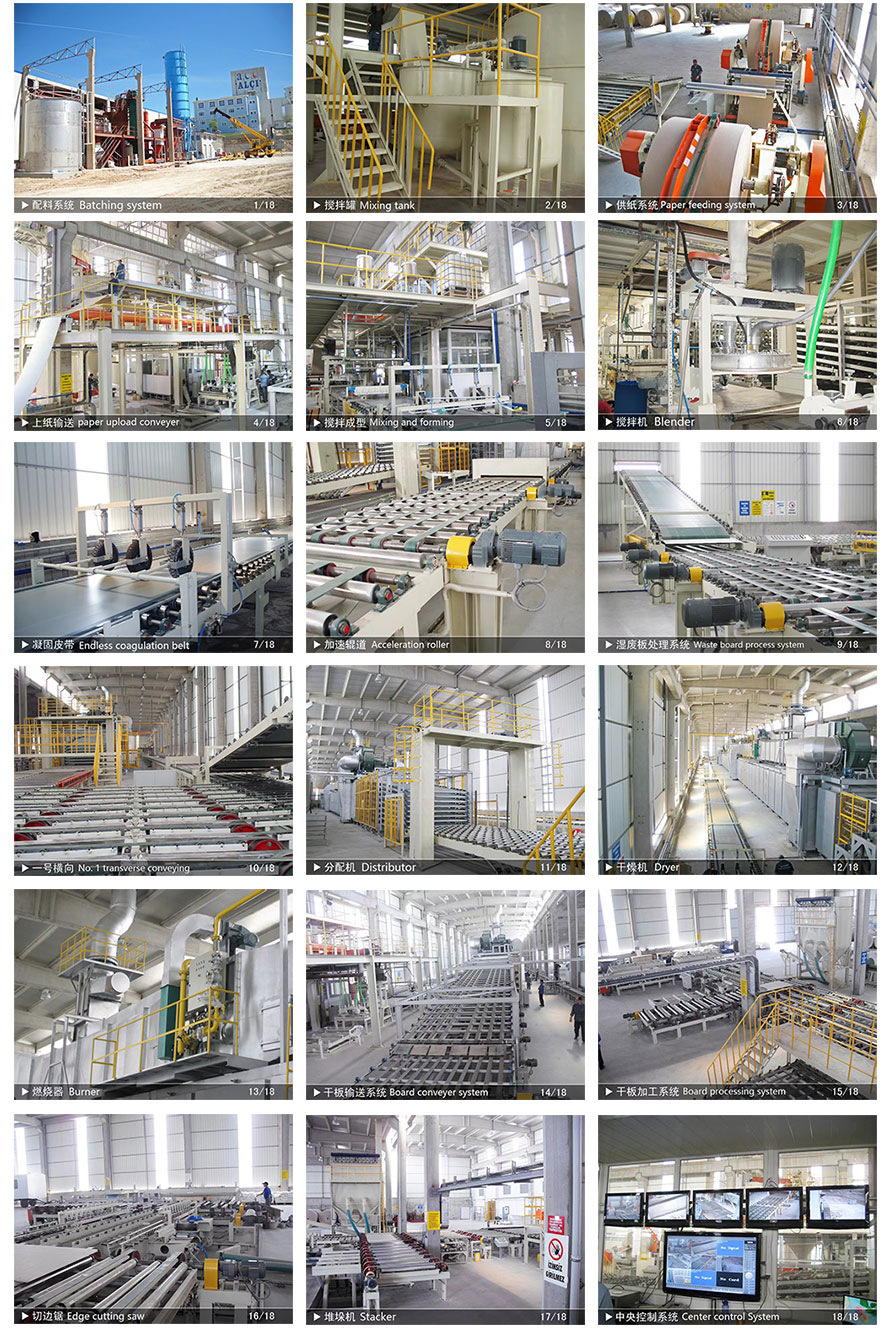

Gypsum board production process principle

Construction gypsum is the main raw material of gypsum board. After processing into a board, an appropriate amount of additives and fibers made from the board core are added to the special board paper for protection. Gypsum board has the characteristics of light weight, sound insulation, heat insulation, strong processing performance and simple construction method.

Gypsum board production process

Gypsum/gypsum powder-drying-refrigeration-clinker calcination-meter-mixing (water, dry mixture, wet material mixture)-pulp molding (protective paper)-coagulation-cutting-drying-filter

-sawing sealing surface --- Stacking

1.Forming conveying part

The paper enters the uncoiler after automatic correction on the uncoiler. After the paper is automatically corrected by the uncoiler, the paper enters the machine under the creasing machine and the vibration platform. The paper falling under the vibration platform from the slurry mixer enters the machine. The specification required for extrusion on the forming machine is gypsum board, and then the initial setting is completed on solidification, the final setting is completed on the roller conveyor belt, the length required after cutting by, after two turns, the plasterboard is beside the left machine at the same time, and then the dispenser is sent to the dryer and dried.

2.Dry part

The boiler provides steam or hot air as a heat source. After the steam is replaced by hot air (or hot air) through the heat exchanger, it is sent to the dryer by the fan to complete the drying task inside the dryer. The drying function is good, and the drying curve of gypsum board drying can be completed, avoiding defects such as excessive combustion and non-drying.

3.Finished product packaging

After drying, the dryer transports the roller to the horizontal system to complete the fixed-length trimming and automatic wrapping of the gypsum board, and then the finished product conveyor is sent to the automatic stacker for stacking, and then the forklift is transported to the packaging area for inspection and packaging.

FAQ:

Q1:Are you trading company or manufacturer ?

A1:We are a professional gypsum board producing line manufacturer for more than 12 years.

Q2:How long is the warranty of your equipment?

A2:1year

Q3:How long is your delivery time?

A3:Generally it is 5-10 days if the goods are in stock. or it is 15- 20 days if the goods are not in stock, it is according to quantity.

Q4:What is your terms of payment ?

A4:We can accept L/C or T/T. Payment< =1000USD, 100% in advance. Payment> =1000USD, 30% T/T in advance,balance before shippment.

Q5:Do you supply spare parts?

A5:Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q6:How will you provide installation &commissioning ?

A6:Arrange practised techicians installing and training oversea as soon as you receive the machines .

Q7: Do you provide samples ? is it free or extra ?

A7: Yes, we could offer the sample for free charge but do not pay the cost of freight.